Fleet Vehicle Replacement Strategy

For some companies, their vehicle replacement strategy is to simply wait until a vehicle goes out of commission to replace it. When leasing a fleet, however, this anti-strategy can hurt rather than help you.

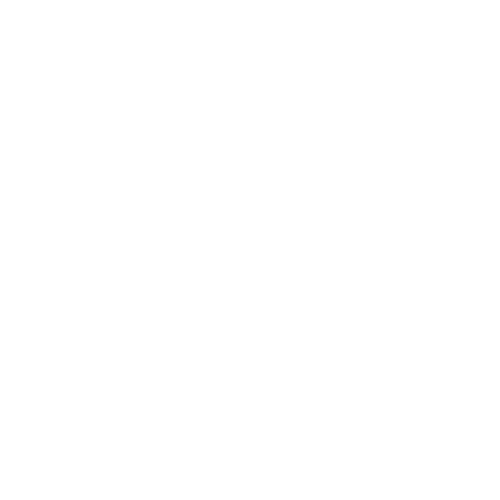

Almost half of the fleet vehicles on the road are past their optimal term, which ultimately impacts a company’s bottom line. Companies that use vehicles past their optimal life are likely to experience:

- 30% decline in annual FMV

- 15% increase in downtime

- 20% in excess fuel spend

Why Come Up with a Fleet Replacement and Lifecycle Management Strategy?

The point of a fleet replacement and lifecycle management strategy is to achieve an even, balanced fleet aging cycle. Some of the benefits of an optimized cycle include:

- Predictable resale values. When you take a strategic approach and plan when to dispose of your vehicles, you maximize resale value.

- Minimized repair and maintenance costs. With a regular cycle, you know what to expect in preventative maintenance costs, and you replace older vehicles before they experience costly breakdowns.

- Happier drivers. Your drivers will appreciate a steady vehicle replacement strategy, as it puts them behind the wheel of a newer, more efficient, and more comfortable vehicle.

- Better fuel savings. Newer vehicles usually have better miles per gallon, meaning in the long run you can significantly slash your fleet’s fuel expenditures. Newer vehicles may also provide alternative fuel options, such as EV.

- Improved safety features. Newer vehicles are usually equipped with more advanced safety technologies, such as forward collision warning and automatic emergency braking, that can protect your drivers and reduce risk. meaning in the long run you can significantly slash your fleet’s fuel and maintenance expenditures.

What is the Optimum Fleet Replacement Schedule?

The point in time where it is best to replace a vehicle is the point that results in the optimal overall cost over the vehicle’s lifecycle. A general rule of thumb is for sedans to be cycled at 36 months or 75,000 miles, and light duty trucks to be cycled at 48 months or 100,000 miles.

However, for the best results, every organization should develop a tailored vehicle replacement and lifecycle management strategy since type of vehicle, amount and type of usage, and vehicle applications all impact the equation.

There are several techniques you can use to accurately calculate the ideal fleet replacement schedule. Fleet replacement calculations involve predictions, forecasts, assumptions, and analysis of available data. You can work with a professional fleet consultant to conduct a vehicle lifecycle analysis and help you understand the best time to replace your vehicles.

Questions to ask when determining your fleet replacement schedule are:

- Is my team fully using the vehicle(s)?

- Does the vehicle(s) have the proper specifications?

- If my team is not fully using the vehicle(s), do I need to replace it?

- Does the vehicle(s) require frequent repairs or maintenance?

Tips for Better Fleet Replacement and Lifecycle Management

In terms of costs of ownership, your replacement cycle can determine whether you come out ahead or behind at the end of your lease term. Here are some ways you can start to improve your fleet replacement strategy:

- Replace Older, Higher-Mileage Units

- Leverage a Guaranteed, Upfront Pricing Remarketing Program like GuaranteeBUY

- Reinvest Vehicle Resale Proceeds into Newer Units

- Select the Most Effective Lease Term

- Invest Fleet Dollars with the Lowest Total Cost of Ownership in Mind

Gain Control Over Your Fleet Vehicle Replacement Strategy

There is a perfect balance you can strike with your fleet vehicle replacement strategy that will give you the best returns on investment. For more information about establishing a fleet replacement schedules that fits your unique needs, contact us or call 866.653.2737.